Cooling Time Calculator

Prevent coating defects with optimal cooling profiles

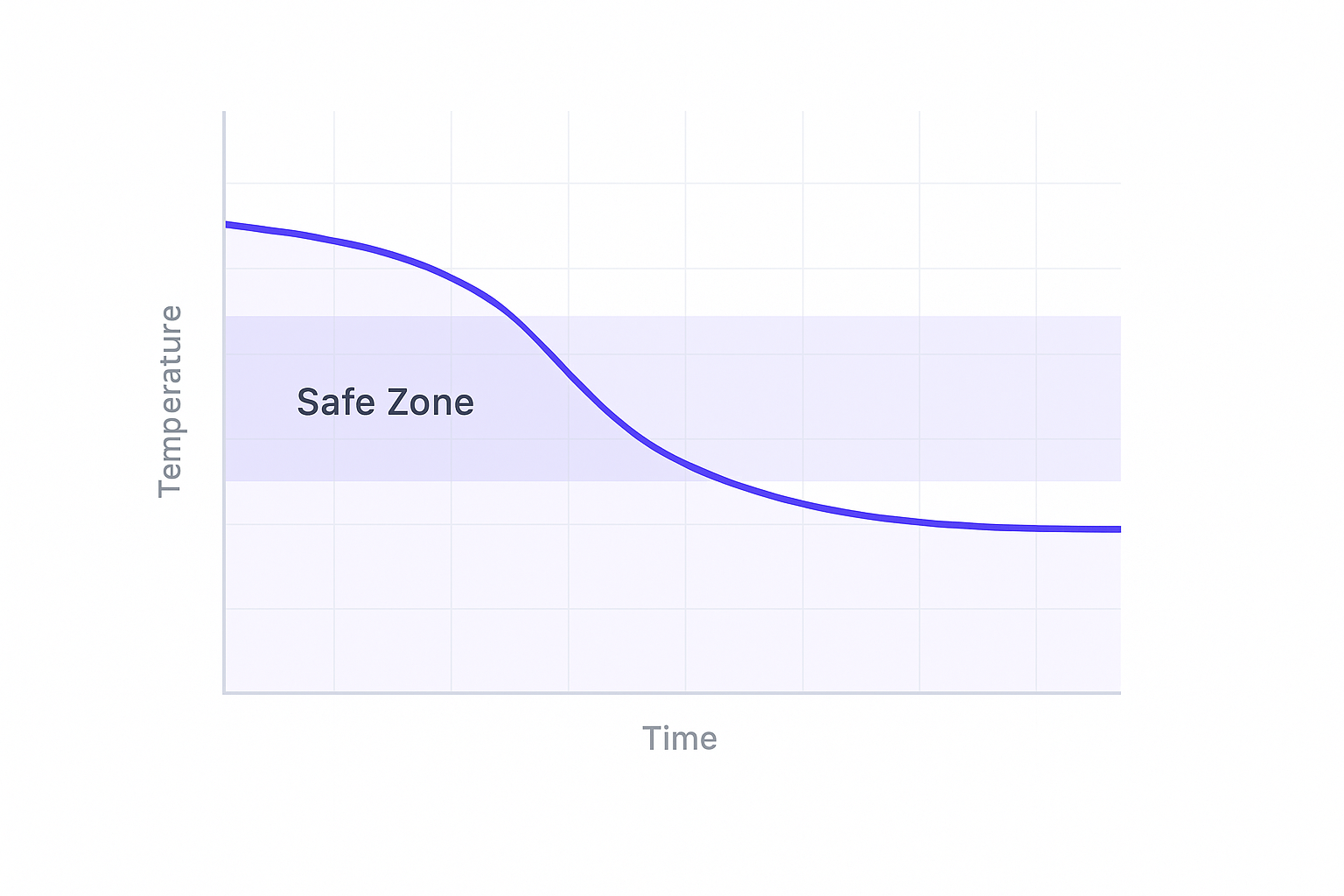

Understanding Cooling Dynamics

🌡️ Thermal Shock

Rapid cooling can cause internal stresses leading to cracking, especially in thick sections or temperature-sensitive coatings.

⚗️ Film Formation

Powder coatings continue crosslinking during cooldown. Proper cooling ensures complete cure and optimal properties.

📐 Dimensional Changes

Different materials have different thermal expansion rates. Controlled cooling prevents warping and dimensional issues.

Cooling Method Comparison

Material Thermal Properties

Thermal Conductivity (W/m·K)

- Aluminum: 237 (cools quickly)

- Carbon Steel: 50 (moderate cooling)

- Stainless Steel: 16 (slow cooling)

- Cast Iron: 55 (moderate cooling)

- Zinc: 116 (fast cooling)

Thermal Expansion (µm/m·K)

- Aluminum: 23 (high expansion)

- Carbon Steel: 12 (moderate)

- Stainless Steel: 17 (high expansion)

- Cast Iron: 10 (low expansion)

- Zinc: 30 (very high expansion)

Cooling Best Practices

✅ Do This

- Cool gradually to prevent thermal shock

- Monitor part temperature, not air temperature

- Use uniform cooling for consistent results

- Allow complete cooldown before handling

- Consider part geometry and mass

- Document cooling profiles for repeatability

❌ Avoid This

- Rapid quenching of thick sections

- Uneven cooling causing warpage

- Handling parts above 60°C

- Cooling sensitive materials too quickly

- Ignoring part geometry effects

- Inconsistent cooling between batches